<font size="54px">Vaccine Poses the Ultimate Challenge to Supply Chain Resilience</font>

Never in history has a pandemic struck a society that is so globally interdependent. The local supply chains of years past have been replaced by global ones that leverage economy of scale and lower-cost production.

The world relies heavily on these supply chains. Their resilience is critical not only to their customers around the globe but also to global companies’ treasuries, bankers, regulators and revenue-dependent governments. So, when bad things like a pandemic or a large natural catastrophe happen, it is often the breakdown of these critical distribution systems that causes the most devastating impact, in terms of both quality of life and economies. That’s why management gurus and insurers have spent decades helping to optimize and strengthen global supply chains, enabling companies to successfully move increasing volumes of high-value goods and services faster, more reliably and with higher margins. When supply chains flounder, it’s deeply troubling.

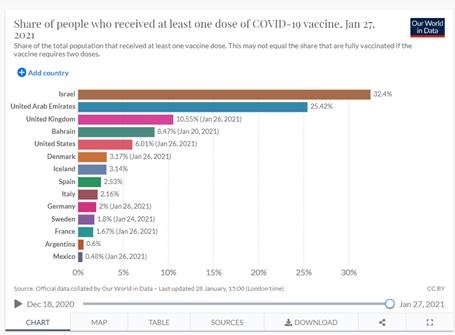

OUR WORLD IN DATA: IMPERIAL COLLEGE LONDON YOUGOV COVID 19 BEHAVIOR TRACKER DATA HUB – 18-JAN-21

Source: Our World in Data

Vaccine distribution epitomizes the importance of global supply chains, now and in the future. The distribution process that is so vital to curtailing the pandemic now presents a supply chain challenge more massive than the world has ever confronted. Moreover, this challenge is likely a dry run for repeatedly testing our resilience in the future with other pandemics, bioterror, or climate crises.

In the meantime, the current vaccine challenge is likely to endure, especially since the length of immunity after vaccine delivery is not precisely known and virus mutation may challenge effectiveness. It is therefore not likely that this challenge will come and go quickly.

The bottom line? A high-performing, global supply chain needs to be rapidly activated for the vaccine, and that supply chain can potentially set the stage for ones in the future that can withstand more frequent, and severe, stress tests.

The hard work has begun

The pandemic has forced pharmaceutical companies, governments, and logistics experts to quickly spin up a supply chain of tremendous scale to deliver a product to a significant proportion of the world’s population of almost 8 billion people. The effort is just getting started; it needs to quickly expand by many orders of magnitude to bring about a measure of social and business normalcy.

Some supply chain risks are known (e.g., fire, natural hazards), as are ways to mitigate them. Other vulnerabilities will surely be revealed and clarified as the vaccine distribution effort increases in scope and scale. The ability to rapidly develop supply chain resilience has never been so essential.

Let’s see what lessons we can apply now, and learn as we go forward, for this and similar challenges in the future.

A lot of action with modest progress

Within the U.S., there are currently two different vaccines available, with varying rates of dose administration by state. In the highest (Alaska) around 11% of the population has received at least a first dose, according to current figures.

There are currently 64 vaccine candidates in human clinical trials and an additional 173 vaccines in pre-clinical evaluation, according to the World Health Organization.1 Decisions will start on product selection, for which quality, not just availability, needs to be the critical first step. Brazil, for example, has downgraded its assessment of the efficacy rate of a coronavirus vaccine made by a Chinese company from 78% to just over 50%. At least 10 countries have ordered that vaccine, according to the New York Times. This potential need for do-overs makes vaccine distribution even more daunting.

As with any product, once a vaccine is developed and certified as required, supply is about manufacturing, assembling, distributing, selling (and in this case administering) the finished goods. Fortunately, the volume of vaccine material is small (typical dose is 0.3ml, or about 6 drops).2 The challenge is getting it there safely and securely.

Colder than Antarctica, all the time

The vaccines currently available in the U.S. both require very low temperatures during transportation and storage. One vaccine needs ultra-cold (cryogenic) temperature between -112F and -76F (-80C and -60C)—think South Pole in winter—and after thawing is good only for up to 5 days in a refrigerator. Not something that can simply be put in a box and sent via a common shipping company. Instead, massive-scale supplies require:

- Ultra-cold facilities known as “freezer farms”

- Cryogenic containers for shipping and storage, which often use liquid nitrogen for cooling

- Reliable and significant power supply to keep things cold

These resources all constitute new investment in facilities, ancillary products, and supplies. The well-proven methods of maintaining supplier resilience are important here: siting of anything to avoid natural hazards (flood, wind, earth movement); use of materials with reliable quality; monitoring (high/low temperature alarms); and backup infrastructure (power and cooling systems with extended outage potential in mind). Urgency, or the excuse that these facilities may only be temporary, doesn’t justify shortcuts on these basics.

Source: 2020 FM Global Resilience Index

Urgency tends to exacerbate the worst supply chain threats. Terrorism, crime, corruption, and warfare are potential vulnerabilities anywhere, but if you’re involved in global distribution, they’re more likely to have far-reaching consequences. Thus, it is vital to use readily available tools to recognize the risk well in advance. At the country level, this resilience index is one such tool. It ranks nearly 130 countries by the resilience of their business environments. One factor in the rankings is supply chain resilience, comprising four drivers: control of corruption (based on World Bank data), quality of transport and utility infrastructure (World Economic Forum), corporate governance (WEF), and supply chain visibility (World Bank). Singapore and Hong Kong have the highest resilience on this measure, and Haiti, Chad and Venezuela have the lowest. Of course, these driving factors also vary locally, so evaluating the region, city, even neighborhood is important as well.

Cybercrime is global, too

But national, regional, and local threats are not the only ones to consider. Now, since everything is digital, hostile actions can come from anywhere.

Cyber attack is always a risk, especially in highly important circumstances like vaccine delivery. In the case of vaccines, relevant cyber systems range from industrial controls and producers’ condition-monitoring processes to the systems hospitals and public health agencies use to track progress and establish priorities. Knowing what these systems are connected to, and how, is a key part of proper IT security (e.g., firewalls and anti-malware). As always, anyone associated with these systems needs to do the easy things with the biggest impact: Update software at every opportunity and ensure employees do not click on suspicious links. Remote workforces, proliferating because of the pandemic, are especially vulnerable to cyber attack. From February to March 2020, a 569% growth in malicious registrations, including malware and phishing, and a 788% growth in high-risk registrations were detected and reported to INTERPOL.3

The workplace, however, is no safe harbor. Essential workers in the office likely face lower levels of security and on-site IT support than in normal times, so it’s important to assess risks related to physical breaches of IT systems, e.g., unauthorized personnel, unlocked doors, unattended computers and random thumb drives.

Redundancy—a good thing in this case

In general, redundancy creates resilience. That means it’s desirable to have second, or ideally, third options for manufacturing, assembling, distributing, and selling products. Redundancy takes time, money and effort, however, so the risk associated with having a single path of supply must be weighed against the cost and delay of duplicating it. Given the urgency, the best path may be to establish the initial supply chain, using all the current best business practices, and monitor its progress (it is possible to track anything, anywhere now with Internet of Things technology)4 while planning a secondary option in case it is needed.

Finally, getting delivered vaccines into the arms of patients is another challenge, but that’s the “last mile” and a multifaceted problem that becomes moot if there is no supply.

This pandemic presents a number of novel challenges. Although the current vaccine supply chain demands added resources in technology, logistics and scale, when we dig deep, vaccine distribution looks a lot like a conventional business problem, just bigger and more complex.

So whether moving medicines, the items associated with them, or household widgets, applying proven supply chain resilience principles, monitoring progress, and then being ready to quickly learn and modify based on what occurs in the next few months are the keys to success. Although pandemics of the past didn’t present the challenge of a globally connected society and integrated distribution, the technologies and means to deliver the vaccines required to end them quickly were not available. They are now, and they need to be put to good use.

As originally published in Forbes.

Learn about Supply Chain Risk Management at FM Global

Follow Lou on LinkedIn.

Read more by Louis Gritzo:

Climate Change Is Threatening Your Company’s Building

Three Reasons America’s Wildfire Costs Will Continue To Get Worse

6 Ways to Quantify and Mitigate Flood Risk

How Businesses Use Data to Outsmart Nature’s Wrath

[1] Draft landscape of COVID-19 candidate vaccines-15 January 2021[Internet]. [cited 2021 Jan 18]. Available from: https://www.who.int/publications/m/item/draft-landscape-of-covid-19-candidate-vaccines

[2] https://www.cdc.gov/vaccines/covid-19/info-by-product/pfizer/downloads/prep-and-admin-summary.pdf

[3] INTERPOL, CYBERCRIME: COVID-19 Impact, August 2020 https://www.interpol.int/en/content/download/15526/file/COVID-19%20Cybercrime%20Analysis%20Report-%20August%202020.pdf